Jersey Barriers are designed to redirect a crash, using the car’s momentum to absorb the impact and slide the vehicle up parallel along the side of the barrier to prevent a rollover. These barriers would be implemented in various states, but would bear the name of the state in which they were developed. The base is 3 inches high and is followed by a 13-inch side slope before the barrier becomes vertical.

Jersey barrier full#

Eventually, in 1959, they settled on a standard barrier height of 32 full inches above the pavement with a 24-inch-wide base. Though the initial barriers were somewhat successful in reducing the impact of collisions, New Jersey state highway engineers continued to tinker with the design, creating progressively larger prototypes based on amounts of observed accidents (as opposed to performing controlled crash testing). Each was anchored to the roadbed by steel dowels and consisted of a 2-inch thick outer layer of white concrete to make it more visible at night. These original barriers measured 19 inches high and 30 inches wide, with 2 inches buried in the road to provide stability. Then, in 1949, the state of New Jersey adopted comparable concrete structures and installed preventative parabolic median barriers on the Jugtown Mountain section of US Route 22 in Hunterdon County, which had a similarly hazardous downgrade to the Ridge Route highway. The most common name for these ubiquitous concrete slabs is “Jersey Barriers”-but why?Ĭoncrete road barriers were first used in California in 1946 they replaced the standard (but weak) wood beam guardrails on the treacherous Grapevine section of the state’s Ridge Route highway-the home of the original “Dead Man’s Curve”-where the roads had a 6 percent downgrade that led to many head-on collisions.

Jersey barrier driver#

But these seemingly simple barriers are actually deceptively sophisticated: Their designs have been well-tested and tweaked to ensure driver safety on both sides of the road in the event of a crash.

Jersey barrier install#

These barriers may also be deployed as part of flood defences, as the fully interlocking design means that no additional mortar, which would be vulnerable to wear in wet conditions, is required to install the defence.Most people take the partitions that divide the traffic on U.S.

Bay boundaries – as well as guiding traffic, Jersey and Legato concrete barriers can also be used to effectively create and delineate parking and storage bays.

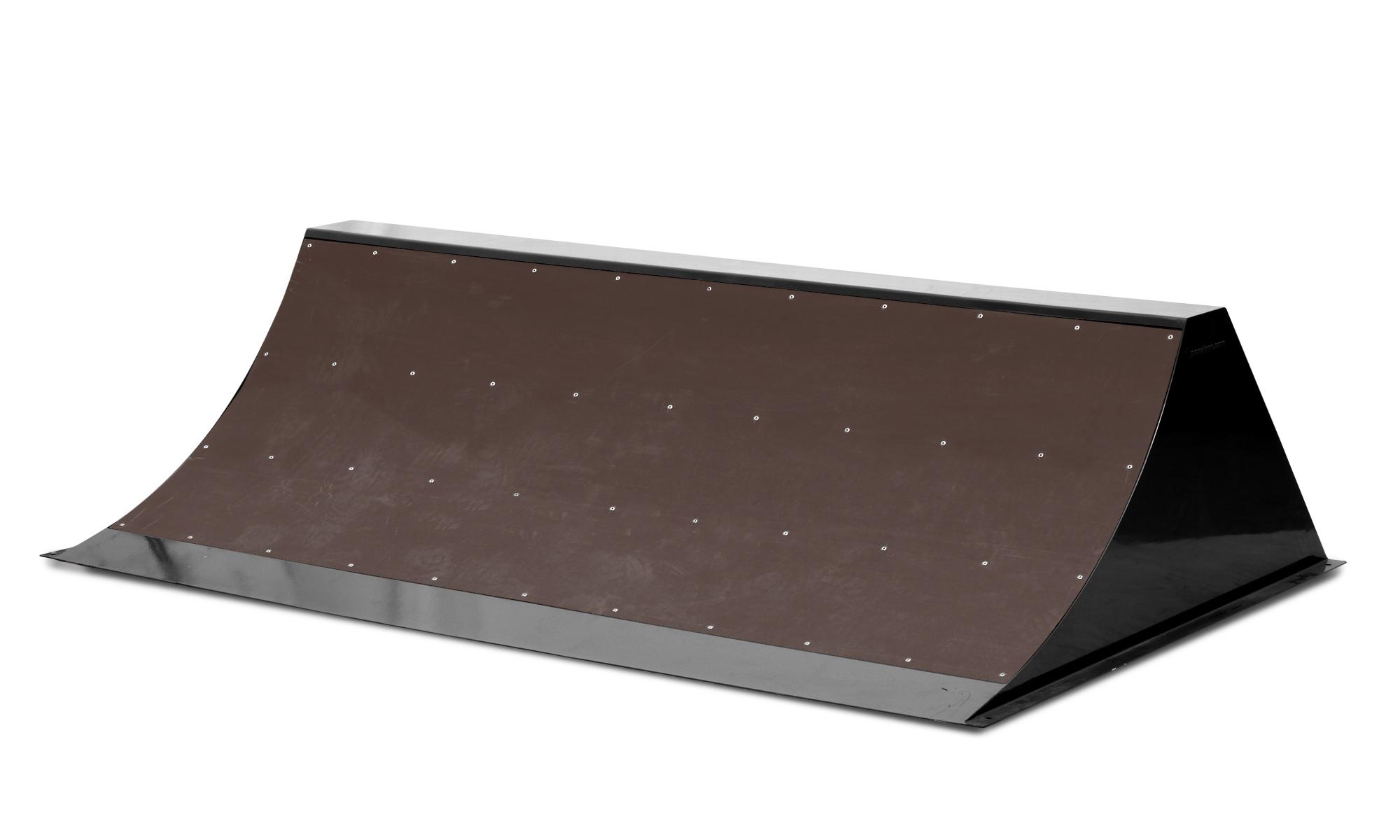

Guiding traffic – whilst other types of barrier systems can also be used for guiding traffic the advantage of concrete systems, particularly Jersey barriers, is that their significant weight and stability means they are not easily dislodged by vibration from transport systems – including trains, and traffic.Blocking view – following accidents or during works, sometimes the sight of a site can be a significant distraction to nearby road users and communities, whilst it may also be necessary to screen works for other privacy or protection reasons.Prevent issues such as fly-tipping as access cannot be gained to do so. Optimise safety from additional hazards, for example by keeping public and vehicles at a safe distance from debris or specific hazards, such as dangerous structures, landslides or deep water.Reducing risk of harm from attacks which use vehicles, such as ram-raiding.This makes concrete systems the optimum choice for long-term barriers to entry and access points in order to: Blocking access – whether this is to a property, commercial premises or plot of land, the weight of a concrete barrier renders it almost impossible to breach. Jersey barriers are also used to reroute traffic and protect pedestrians and workers during highway construction. It is designed to minimize vehicle damage in cases of incidental contact while still preventing vehicle crossovers resulting in a likely head-on collision. A Jersey barrier, or Jersey wall, is a modular concrete or plastic barrier employed to separate lanes of traffic.

0 kommentar(er)

0 kommentar(er)